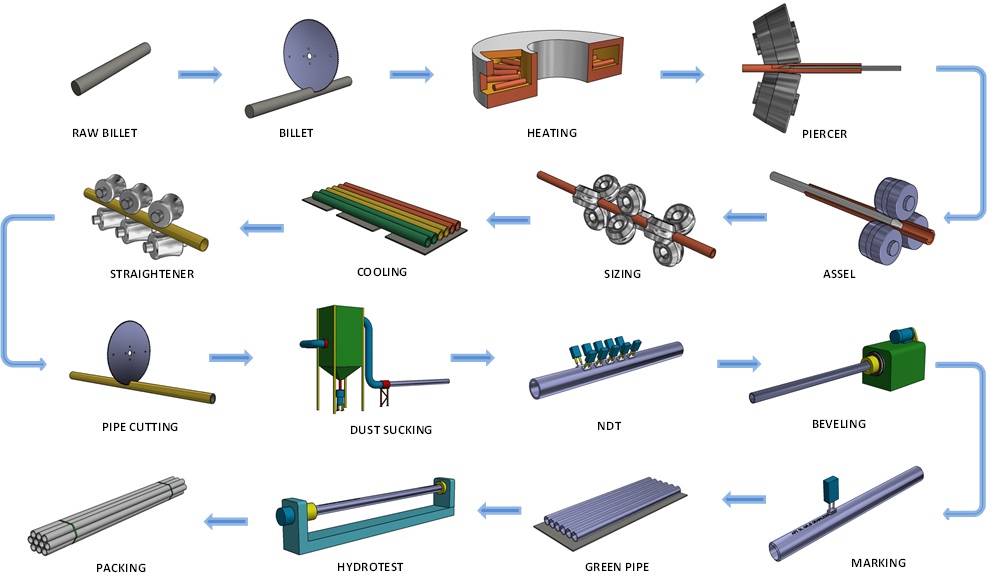

HOT ROLL MILL

In the Hot Roll Mill Process, a solid round billet is used as raw material. It is heated in a rotary hearth heating furnace and then pierced by a piercer. The pierced billet or hollow is rolled by a mandrel mill to reduce the outside diameter and wall thickness which forms a multiple length shell. The shell is then sized by a sizing mill to the specified dimensions, then sent to the cooling bed as green pipe or as rolled products. This process completely run under hot working conditions. From this step, the green pipe goes through the straightener. Under strict inspection and testing referring to the requirements set by the standard, green pipe becomes a specific finished product which is ready for shipment.

Hot Roll Mill Process